1️⃣ Introduction to Fan Coil Units (FCU)

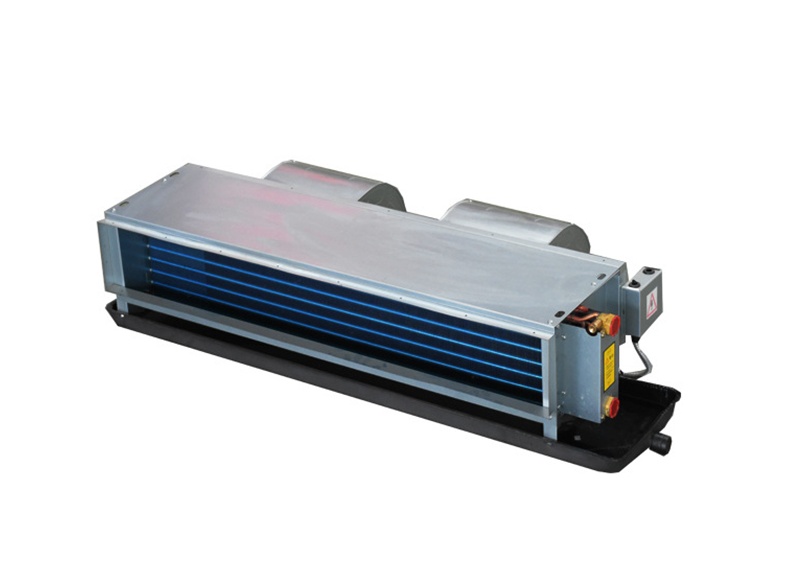

A Fan Coil Unit (FCU) is an essential component in a central air conditioning system, primarily responsible for temperature and humidity control. It consists of a fan, coil (heat exchanger), motor, air filter, and casing. FCUs are available in various installation types, including:

- Exposed Floor-standing (Vertical)

- Concealed Floor-standing (Vertical)

- Exposed Ceiling-mounted (Horizontal)

- Concealed Ceiling-mounted (Horizontal)

- Column-type (Exposed & Concealed)

- Ceiling Cassette Type

🔧 Key Components:

- Casing: Made of lightweight steel with fixed or adjustable air grilles.

- Fan: Uses cross-flow technology to enhance airflow efficiency.

- Motor: A single-phase capacitor motor with low noise and three-speed settings (High, Medium, Low).

- Coil: Typically made of copper tubes with aluminum fins for efficient heat exchange.

- Air Filter: Slide-in drawer type, used to filter return air and ensure air quality.

- Thermostat: Automatically adjusts the fan coil output based on room temperature.

2️⃣ Pre-installation Requirements

🔹 Material Requirements:

- The FCU and accessories must come with factory quality certification or a testing certificate.

- The model, installation type, air outlet direction, and water inlet position must match design specifications.

- All main and auxiliary materials used during installation must meet design standards and have quality certifications.

🔹 Site Conditions Before Installation:

- The FCU and all necessary tools should be available on-site.

- Power and water supply must be accessible for pre-installation testing.

- Construction should be completed (roof waterproofing, wall and floor finishing) before installation begins.

- The installation position must meet design requirements, and main ductwork should be completed with correctly positioned branch pipe outlets.

3️⃣ Fan Coil Unit Installation Process

🔹 Step 1: Equipment Inspection

Before installation, check the FCU for the following:

✔️ The fan should rotate freely without mechanical friction.

✔️ The motor wiring should be correct, and there should be no electrical leakage.

✔️ Perform a three-speed trial run to ensure smooth operation.

✔️ Inspect the coil and motor casing for damage or rust.

✔️ Conduct a water pressure test at 1.5 times the working pressure for 2-3 minutes—no leaks should occur.

🔹 Step 2: Support Bracket Installation

- The FCU must have independent support brackets.

- Brackets must be securely fixed to the building structure without affecting structural safety.

- DO NOT weld brackets onto load-bearing steel beams or reinforcement bars.

- For horizontal ceiling-mounted FCUs, ensure:

- The brackets are level and secure.

- The suspension rods do not swing freely.

- Use double nuts and 3mm rubber gaskets for vibration isolation.

🔹 Step 3: Mounting the Fan Coil Unit

1️⃣ Positioning: Ensure the FCU is level and securely fastened in the designated location.

2️⃣ Air Duct Connection:

- Use flexible ducting between the FCU and the air supply/return ducts to reduce vibration.

- Ensure proper insulation to prevent condensation issues.

3️⃣ Drainage Slope: - The FCU should be slightly sloped towards the condensate drain outlet.

- Ensure proper drainage to avoid water accumulation.

4️⃣ Access Panel for Concealed Units: - Leave a maintenance access panel in the ceiling for servicing.

5️⃣ For Floor-mounted Units: - Ensure the unit is firmly secured with the correct position and height.

4️⃣ Pipe Installation

🔹 Step 1: Connecting the Chilled/Hot Water Pipes

- Use steel pipes or copper pipes for supply and return connections.

- Ensure pipes are aligned properly to avoid excessive bending.

- Use a wrench to hold the connection point while tightening fittings to prevent damage.

🔹 Step 2: Flushing the System

- Flush the entire piping system before connecting to the FCU to remove debris.

- This prevents blockages in the heat exchanger.

🔹 Step 3: Condensate Drain Pipe Connection

- Use a transparent drain hose (≤150mm) for visual inspection.

- The drainpipe must be securely connected, sloped correctly, and free from kinks.

🔹 Step 4: Valve & Filter Installation

- Install shut-off valves and filters close to the FCU.

- Check air release valves to ensure proper operation.

- If the chilled water system has a bypass valve, use a two-way control valve.

- If there is no bypass valve, use a three-way control valve.

5️⃣ System Testing & Commissioning

🔹 Step 1: Pre-checks Before Testing

✔️ Motor insulation resistance should be >0.5MΩ.

✔️ Wiring connections for the thermostat, fan speed control, and motor should be correct.

🔹 Step 2: Trial Operation

1️⃣ Test the Fan:

- Perform a “jog test” to check for abnormal noise.

- Ensure the impeller and casing do not rub against each other.

2️⃣ Check Airflow & Speed: - Use a soft ribbon or anemometer to measure airflow at different speeds.

3️⃣ Verify Thermostat Functionality: - Adjust the temperature settings to test the control valve operation.

6️⃣ Quality Standards & Final Inspection

✔️ Quality Requirements:

- The FCU must be installed level and securely fastened.

- No leaks should be present in the water connections.

- The condensate drain should have a proper slope to ensure smooth drainage.

- Air ducts must be tightly sealed to prevent air leaks.

✔️ Inspection Methods:

- Use a leveling tool and plumb line for proper alignment.

- Conduct a pressure test on water connections.

- Observe airflow and check for leaks or abnormal noise.

7️⃣ Protection & Maintenance

✔️ Storage & Handling:

- Store FCUs in a dry, covered area before installation.

- Protect them from rain, snow, and mechanical damage.

✔️ Winter Protection: - Drain water from the coils after pressure testing to prevent freezing damage.

✔️ During Installation: - Install FCUs immediately after delivery to avoid on-site damage.

- Coordinate with other construction work to prevent accidental damage.

8️⃣ Common Installation Issues & Solutions

| Issue | Cause | Prevention |

|---|---|---|

| Freezing in winter | Water left inside coils | Drain all water after testing |

| Physical damage during transport | Improper handling | Store properly, handle carefully |

| Blocked heat exchanger | Dust/debris in system | Flush pipes before installation |

| Clogged condensate drain | Dirt accumulation | Clean the drain pan regularly |

🔹 Conclusion

A properly installed Fan Coil Unit (FCU) ensures efficient cooling/heating, low noise, and long-term reliability. Key steps include:

✅ Ensuring proper positioning and securing the unit

✅ Using flexible connections to prevent leaks & vibrations

✅ Maintaining proper drainage slope for condensate removal

✅ Testing airflow, fan speeds, and temperature controls

For best performance, regular maintenance, cleaning, and periodic system checks are recommended! ✅ 😊