Fan Coil Unit: Types, Selection Guide & Troubleshooting

What is a Fan Coil Unit?

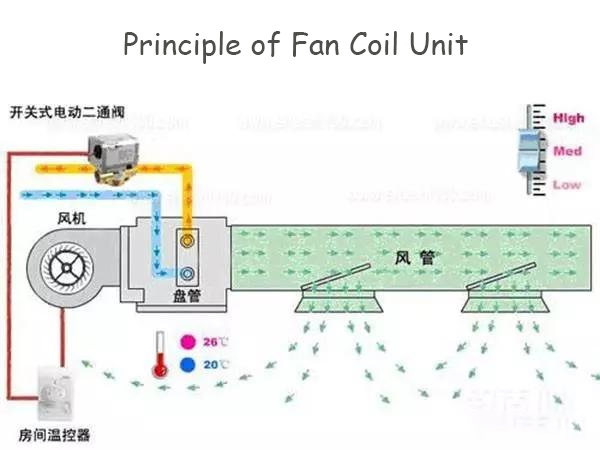

In large central air conditioning systems, the fan coil unit (FCU) is a key component and an ideal terminal product. It integrates a fan and a heat exchanger coil, where indoor or mixed outdoor air is cooled or heated before being distributed indoors. This process ensures optimal indoor temperature control for enhanced comfort.

Working Principle of Fan Coil Units

FCUs operate by forcing air through a heat exchanger, where it is either cooled or heated. This process enhances convective heat exchange, allowing for rapid temperature adjustment in a room.

Main Components of a Fan Coil Unit

? Fan: Driven by a multi-speed, low-noise induction motor, the fan speed is controlled via voltage regulation, offering high, medium, and low-speed settings. It serves as both an airflow source and a heat transfer enhancer, while also being a key source of operational noise.

? Coil: A finned-tube air-to-water heat exchanger, where chilled or hot water circulates inside the tubes. Due to condensation on the coil’s surface, it operates in a wet condition, ensuring both heat and moisture exchange for improved efficiency. Coils typically have 3 to 4 rows of tubes to handle the room’s cooling or heating load.

? Condensate Drain Pan: Positioned beneath the coil, it collects and drains condensation through an outlet pipe.

? Air Filter: Positioned under the coil, it traps dust and impurities, preventing them from entering the system.

Fan Coil Unit Categories & Models

Two Primary Circulatory Systems

✔ Water Circulation: Chilled or hot water from a central system circulates through the heat exchanger.

✔ Air Circulation: The fan continuously recirculates room air, cooling or heating it to maintain a stable temperature.

Classification by Structure

- Floor Standing

- Ceiling Concealed (Horizontal & Vertical)

- Wall-Mounted

- Cassette (Ceiling-Recessed)

Classification by Installation

- Exposed (Visible Casing)

- Concealed (Hidden in Ceiling or Walls)

Classification by Water Connection

- Left-Hand Connection

- Right-Hand Connection

Classification by Thickness

- Ultra-Thin

- Standard Thickness

Classification by Drainage System

- Standard

- Luxury (with Condensate Pump)

Classification by Static Pressure

- 0 Pa

- 12 Pa, 30 Pa, 50 Pa, 80 Pa

Classification by Coil Configuration

- 2-Row Coil

- 3-Row Coil

Classification by Pipe System

- 2-Pipe System:

- Summer: Chilled water for cooling

- Winter: Hot water for heating

- 4-Pipe System:

- Suitable for luxury buildings, allowing simultaneous cooling and heating in different rooms.

? More copper tubes = better cooling performance

- 2-row coil: 16 tubes (8 per row)

- 3-row coil: 24 tubes (8 per row)

Key Factors in Fan Coil Unit Selection

✅ Cooling Capacity

- Based on calculated cooling load, with adjustments for fresh air supply.

- If fresh air enters directly from outside, it increases the total cooling load.

- If an independent fresh air system is used, only the room cooling load needs to be considered.

✅ Airflow Volume

- Determines air quality by maintaining appropriate air changes per hour.

- Nominal airflow values are based on ideal conditions, so actual values should be adjusted by 20-30% for real-world scenarios.

✅ Supply & Return Airflow Configuration

- Impacts temperature uniformity and air distribution.

- Improper design may lead to air short-circuiting, reducing efficiency.

- Fan coil selection should match the room’s depth, ceiling height, and layout.

✅ Other Factors

- Noise control: Should be ≤40 dB; additional silencers may be needed.

- Installation quality: Ensure proper insulation and condensate drainage.

- System type: Horizontal vs. Vertical installation affects water drainage and ceiling height requirements.

Installation Considerations for Fan Coil Units

✔ Ensure level installation using Ø10mm anti-rust hanging rods.

✔ Maintain proper spacing from the ceiling for airflow.

✔ Conduct a 2-hour pressure test (0.6 MPa) to ensure no leaks.

✔ Proper insulation:

- Water pipes: 20mm thick insulation

- Condensate pipes: 10mm thick insulation

✔ Maintain a 1% slope in the condensate drain for proper flow.

✔ Avoid ceiling cassette units in rooms over 3m high, as warm air may not circulate effectively.

✔ Soft piping connections are essential to prevent vibration-induced leaks.

✔ Use stainless steel flexible connectors to minimize vibration transmission.

✔ Install a Y-strainer on the water inlet to prevent dirt and debris from clogging the system.

✔ Install two-way control valves on the return pipe in energy-efficient systems.

✔ Ensure electrical grounding to prevent electrical hazards.

✔ Each fan coil unit must have its own control switch to prevent motor damage.

Common Fan Coil Unit Issues & Troubleshooting

1. Low Airflow & Poor Cooling Performance

? Cause: Clogged air filter or blocked coil fins.

✔ Solution: Regularly clean the air filter (at least quarterly). Dust buildup can reduce airflow and increase motor load, leading to higher energy consumption.

2. Increased Noise with Higher Fan Speeds

? Possible Causes:

- Loose mounting brackets causing vibrations

- Foreign objects inside the air ducts

- Fan blade deformation or motor bearing failure

✔ Solution:

- Tighten support brackets

- Remove any foreign objects

- Inspect fan blades and motor bearings

3. Fan Motor Not Running

? Possible Causes:

- Electrical failure

- Blown fuse

- Control switch malfunction

✔ Solution:

- Check power supply

- Replace fuses

- Inspect and test control switches

4. Temperature Variations Despite Normal Airflow

? Cause: Insufficient or imbalanced water flow.

✔ Solution: Adjust valves and water flow settings to ensure even temperature distribution.

5. Water Leakage or Dripping

? Possible Causes:

- Clogged condensate drain

- Poor pipe insulation

- Loose piping connections

✔ Solution:

- Clear drain obstructions

- Ensure proper insulation thickness

- Secure pipe fittings with stainless steel flexible connectors

Final Thoughts

Proper selection, installation, and maintenance of fan coil units are crucial for optimal cooling and heating performance in a central HVAC system. By considering airflow, cooling capacity, noise levels, and proper installation practices, you can ensure efficient operation and extended system lifespan.